The ADC using the voltage on the VREF pin as a reference to compare ADC input against. VREF should be set to a value close to VCC (1)(pg 74). Vcc is 3.3V. The Accelerometer is tuned to operate at 3.0V (but can accept any voltage from 2.4 to 5 volts) (2)(pg 5). Ideally it would be good to set the VREF pin to 3.0V, but on the Logomatic V2 Board VREF is tied directly to VCC.(3)

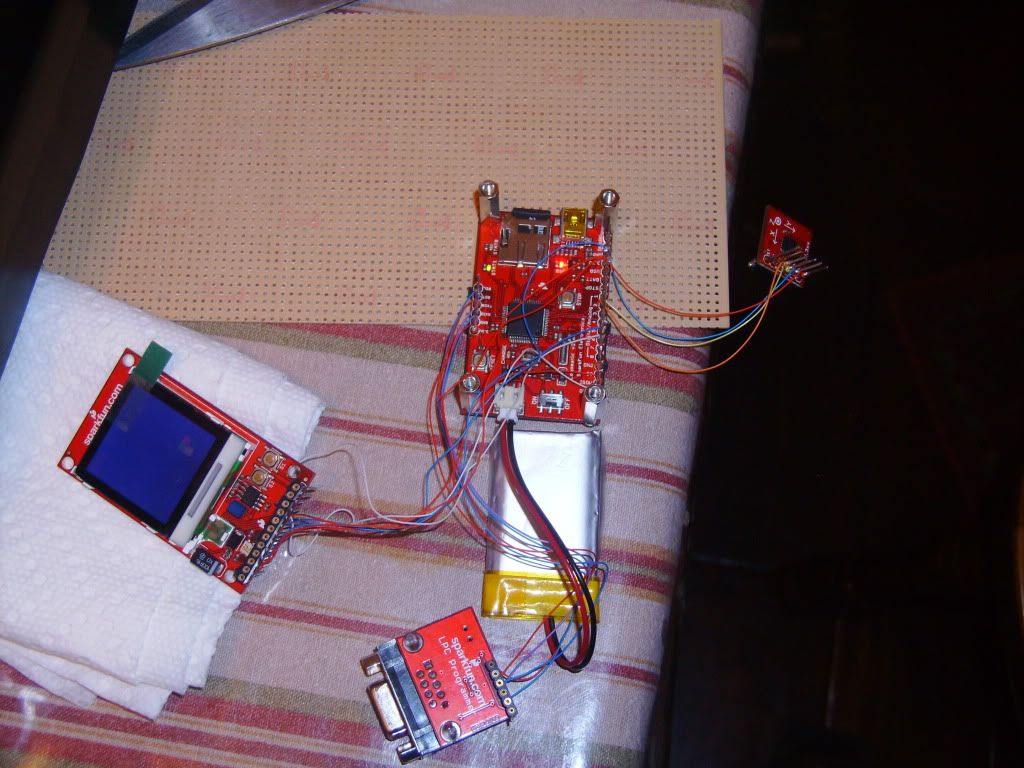

The student connected the accelerometer to the LPC2148 in the following manner.

LPC-PIN ADXL-PIN

P1 X

P2 Y

VCC VCC

GND GND

The student then modified adc.h and adc.c from Phillips and produced MyAccelDriver.h and MyAccelDriver.c. main.c was also modified to test the functionality of the new accelerometer driver.

//****************************

// MyAccelDriver.h

//****************************

// Header file for ADC setup

// ELH April 3rd 2011

// The code herein was adapted from adc.h created Phillips Semiconducter Inc.

#ifndef _MY_ADC_

#define _MY_ADC_

#define ADC_CLOCK 3000000

#define ADC_MAX 3

#define ADC_MIN 2

#define ADC_OFFSET 0x10

#define ADC_INDEX 4

#define ADC_DONE 0x80000000

#define ADC_OVERRUN 0x40000000

#define ADC_ADINT 0x00010000

#include "type.h"

extern void ADCInit( DWORD clock);

extern WORD ADC0_Read( BYTE channelNum );

#endif

//****************************

// MyAccelDriver.c

//****************************

// The code Herein was adapted from adc.c created Phillips Semiconducter Inc.

include "LPC214x.h"

#include "type.h"

#include "target.h"

#include "MyAccelDriver.h"

void ADCInit( DWORD clock)

{

// initialize pins 2 and 3 of ADC0 for ADC input

// first clear bits 29:26 of PINSEL1 without modifying any other bits(pins)

// 11000011111111111111111111111111b

PINSEL1 &= 0xC3FFFFFF;

// now set bit 28 and 26 without modifying any other bits (pins)

// 00010100000000000000000000000000b

PINSEL1 |= 0x14000000;

AD0CR = ( 0x01 << 0 ) | // SEL=1,select channel 0, 1 to 4 on ADC0

( ( Fpclk / clock - 1 ) << 8 ) | // CLKDIV = Fpclk / 1000000 - 1

( 0 << 16 ) | // BURST = 0, no BURST, software controlled

( 0 << 17 ) | // CLKS = 0, 11 clocks/10 bits

( 1 << 21 ) | // PDN = 1, normal operation

( 0 << 22 ) | // TEST1:0 = 00

( 0 << 24 ) | // START = 0 A/D conversion stops

( 0 << 27 ); // EDGE = 0 (CAP/MAT singal falling,trigger A/D conversion)

}

WORD ADC0_Read( BYTE channel )

{

DWORD regVal;

WORD ADC_Data;

/* channel number is 2 through 3 */

if ( channel > ADC_MAX || channel < ADC_MIN)

{

channel = 2;

}

// clear channel bit

AD0CR &= 0xFFFFFF00;

// start conversion on a given channel

AD0CR |= (1 << 24) | (1 << channel);

while ( 1 ) // wait until end of A/D convert

{

regVal = *(volatile unsigned long *)(AD0_BASE_ADDR + ADC_OFFSET + ADC_INDEX * channel);

/* read result of A/D conversion */

if ( regVal & ADC_DONE )

{

break;

}

}

// stop ADC now

AD0CR &= 0xF8FFFFFF;

// save data when it's not overrun otherwise, return zero

if ( regVal & ADC_OVERRUN )

{

return ( 0 );

}

ADC_Data = ( regVal >> 6 ) & 0x3FF;

return ( ADC_Data ); // return A/D conversion value

}

//*******************************************************

// main.c

// Tests Screen and Accelerometer drivers

//*******************************************************

//Included Libraries for the LPC2148 ARM

#include "LPC214x.h" //Holds general addresses for the LPC2148 (Register Names, Interrupts addresses, Port Names/Numbers etc...)

#include "MyLCD_Driver.h"

#include "MyAccelDriver.h"

#include "system.h"

#include "target.h"

//General Definitions for Code Readability

//The pin numbers were found on the UberBoard v2 Schematic

#define RED_LED (1<<2) //The Red LED is on Port 0-Pin 18

#define GREEN_LED (1<<11) //The Green LED is on Port 0-Pin 19

int main (void)

{

int isRed = 1;

//*******************************************************

// Initialization

//*******************************************************

IODIR0 |= RED_LED | GREEN_LED;// | BLUE_LED; //Set the Red, Green and Blue LED pins as outputs

IOSET0 = RED_LED | GREEN_LED;// | BLUE_LED; //Initially turn all of the LED's off

LCDInit();

LCDClear(BLACK);

//Initialize ADC (just initializes channels 2 & 3 of ADC0

ADCInit(ADC_CLOCK);

//*******************************************************

// Main Code

//*******************************************************

LCDTestPixelSetOrder();

LCDPutStr("abcdefghijklm", 122, 122, RED, BLACK);

LCDPutStr("nopqrstuvwxyz", 122, 116, RED, BLACK);

LCDPutStr(" !&\"$%'()*+,-./", 122, 110, RED, BLACK);

LCDPutStr("0123456789:;?", 122, 104, RED, BLACK);

LCDPutStr("@[\\]^_`",122,98,RED,BLACK);

delay_ms(2000);

LCDSetArea(BLACK, 0, 98, 128, 30);

while(1)

{ //Now that everything is initialized, let's run an endless program loop

// which flashes LEDs and read the ADC

if (isRed == 1)

{

IOCLR0 = RED_LED; //Turn on the Red LED

IOSET0 = GREEN_LED;// | BLUE_LED; //Make sure Green and Blue are off

isRed = 0;

}

else

{

IOCLR0 = GREEN_LED; //Now turn the Green LED on

IOSET0 = RED_LED;// | BLUE_LED; //and turn off Red and Blue

isRed =1;

}

// Read the two ADC channels and output them to the screen.

WORD x = ADC0_Read(3);

WORD y = ADC0_Read(2);

// Report the values obtained from the accelerometer

// and the ADC

LCDPutWORD(x, 122, 122, RED, BLACK);

LCDPutWORD(y, 122, 116, RED, BLACK);

delay_ms(1000); //Delay for a second

}

return 0;

}

// End code files

(1) LPC214x Users Manual

(2) ADXL320 Datasheet

(3) Logomatic V2 Schematic

No comments:

Post a Comment